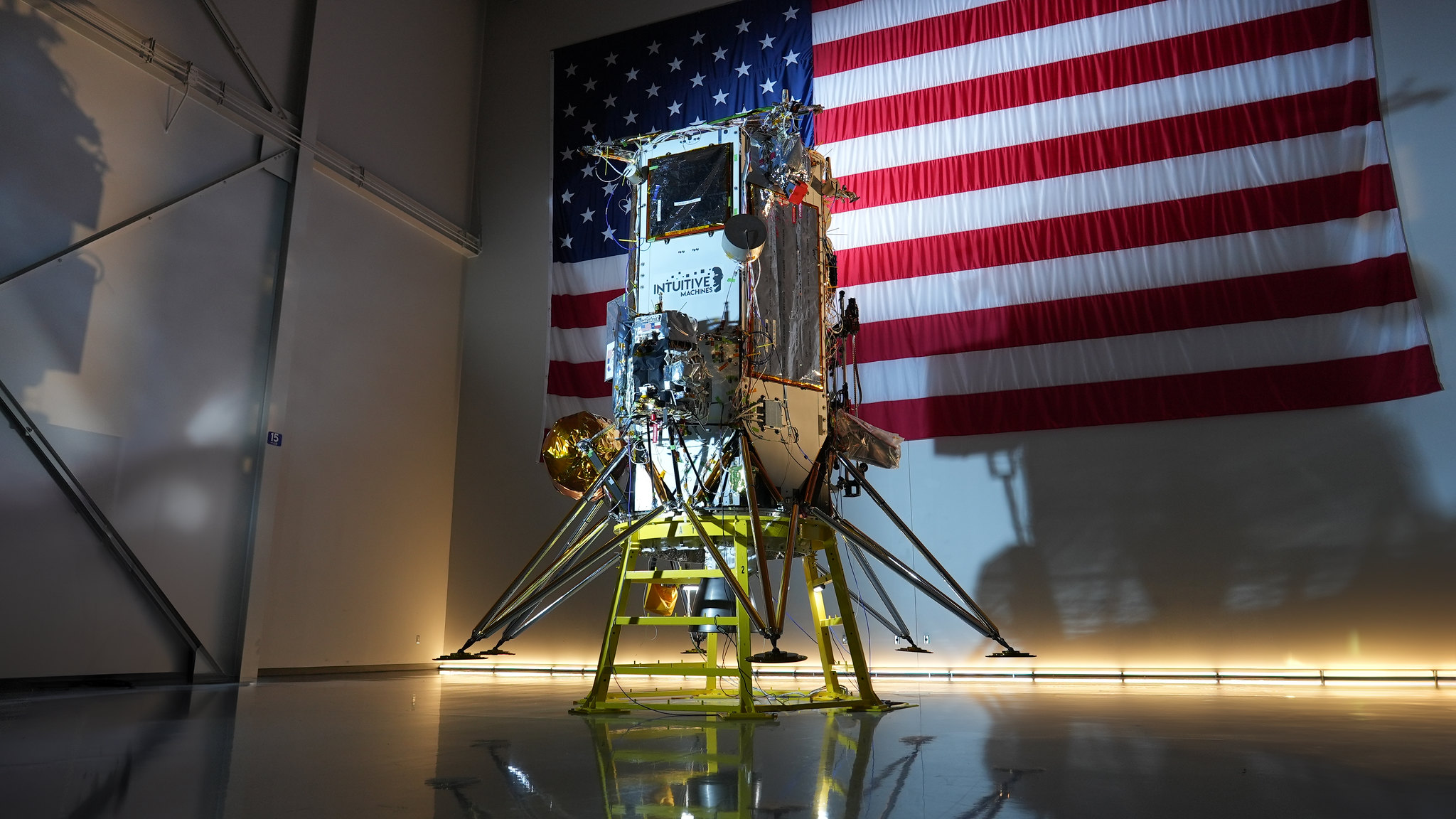

Intuitive Machines Streamlines Aerospace Manufacturing with Boltline

“Building lunar landers demands precision, speed, and reliability. Boltline’s real-time visibility and automated workflows not only save us time and costs but ensure we meet critical mission deadlines while minimizing risks of failure.”

— Jack ‘2Fish’ Fischer, SVP, Production & Operations at Intuitive Machines

Overview

Intuitive Machines is building the future of lunar exploration – landing payloads on the Moon with speed, precision, and reliability. But behind each launch is a complex manufacturing challenge: managing thousands of parts, ensuring compliance, and keeping mission timelines on track. They turned to Boltline’s cloud-based manufacturing platform to make it happen.

Challenges

Developing a lunar lander involves intricate processes and stringent requirements, with no margin for error. Intuitive Machines faced significant challenges:

-

Complex Material Handling: Tracking thousands of parts and certifications across multiple sites was manual and error-prone, risking delays

-

Audit Traceability: Strict aerospace regulations demanded complete digital records, or risk multi-million-dollar penalties

-

Lost Hardware: Misplaced components led to production delays and replacement costs

-

Testing Schedule Conflicts: Inefficient scheduling caused bottlenecks, threatening tight, mission-critical timelines

-

Procedural Inefficiencies: Manual processes in the propulsion department burdened development and increased rework risk

Solution

Intuitive Machines partnered with Boltline to integrate its cloud-based platform into its manufacturing ecosystem, addressing these challenges with:

-

Real-Time Inventory Tracking: Boltline’s inventory module provided end-to-end visibility from shelf to assembly, eliminating lost hardware and optimizing material handling

-

Complete Lifecycle Traceability: An automated digital thread provided end-to-end traceability, which simplified audits and ensured compliance

-

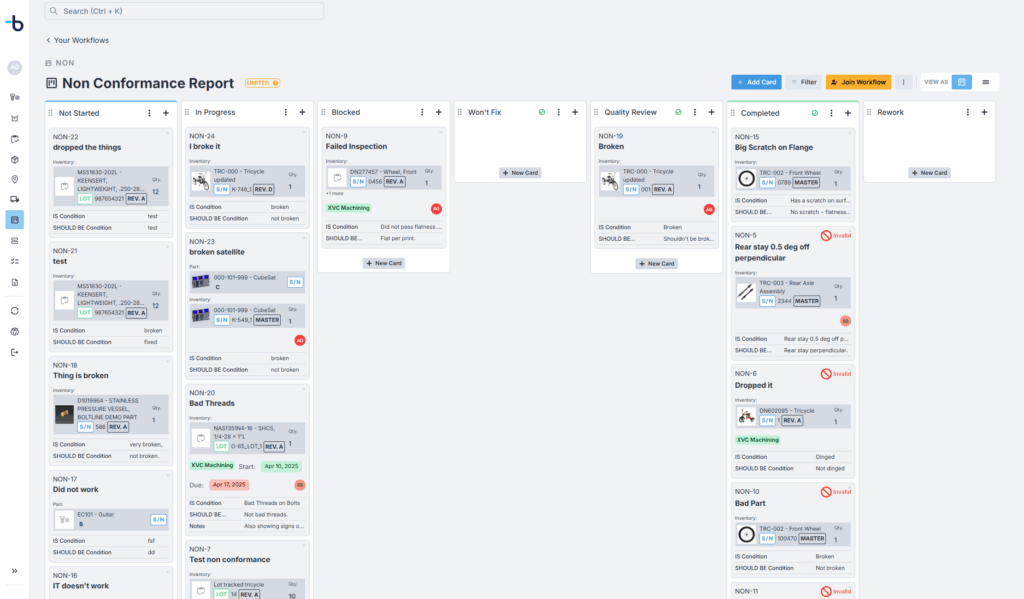

Automated Workflows: Work Plans and Kanban automation streamlined production tasks, enhancing procedural efficiency

-

Order Management: Integrated order and approval processes kept testing on schedule

-

Version Control & Change Management: Boltline’s tools tracked changes to assemblies and procedures, preventing costly miscommunication

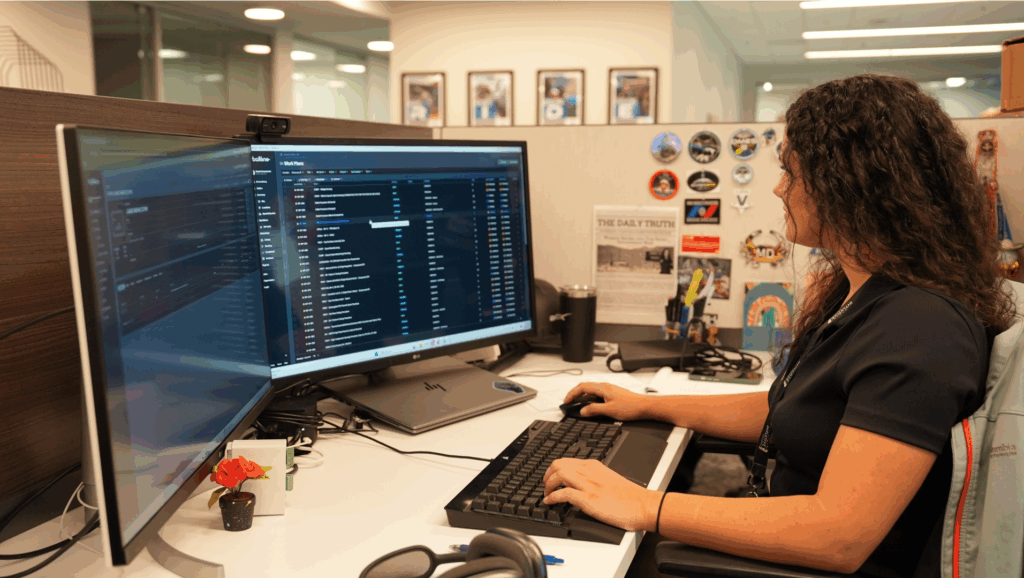

“Boltline’s team collaborated closely with us to roll out the platform, delivering a seamless, intuitive solution that keeps our teams aligned and our processes on track.”

— Rachel Jeansonne, IT at Intuitive Machines

Results: $6M Annual Savings + On-Time Spacecraft Delivery

Boltline’s platform accelerated production cycles, reduced costs, and maintained mission timelines.

Boltline’s implementation delivered transformative outcomes, enabling Intuitive Machines to meet mission-critical deadlines, reduce operational costs, and mitigate risks of failure:

-

Faster Development Cycles: Automated scheduling and workflows eliminated bottlenecks

-

Enhanced Reliability: Boltline’s real-time inventory tracking reduced errors and delays

-

Audit-Ready Compliance: ITAR-compliant traceability, simplified inspections, and reduced pedigree review time

-

Scalable Production: Boltline significantly reduced labor and rework costs, freeing resources for future missions

-

Continuous Improvement: Real-time data visibility empowered data-driven decisions, allowing Intuitive Machines to identify and address inefficiencies proactively, enhancing process reliability and mission success

“Boltline’s real-time visibility gives us confidence in our processes, helping us avoid costly mistakes and deliver spacecraft on time, every time.”

— James Blakeslee, VP Engineering at Intuitive Machines

Technology Used: Boltline at Intuitive Machines

-

Boltline Parts Library: Managed design-time descriptions and bills of materials for every part, ensuring accuracy

-

Boltline Inventory: Enabled real-time tracking and querying of parts across the supply chain, reducing losses

-

Boltline Work Plans & Workflows: Automated workflows and Kanban boards for efficient task management and error reduction

-

Boltline Orders: Streamlined order management with integrated inventory and approval processes, minimizing conflicts

About Intuitive Machines

Intuitive Machines is a diversified space technology, infrastructure, and services company focused on fundamentally disrupting lunar access economics. In 2024, Intuitive Machines successfully soft-landed the Company’s Nova-C class lunar lander, on the Moon, returning the United States to the lunar surface for the first time since 1972. In 2025, Intuitive Machines returned to the lunar south pole with a second lander. The Company’s products and services are focused through three pillars of space commercialization: Delivery Services, Data Transmission Services, and Infrastructure as a Service. For more information, please visit intuitivemachines.com.

Unlock Manufacturing Excellence with Boltline

Boltline Team is ready to keep your mission on track: See Boltline in Action