ispace Boosts Lunar Mission Success with Boltline’s Precision Traceability

“Building lunar landers for the far side of the Moon demands unwavering traceability and efficiency. Boltline’s real-time tracking and flexible workflows have streamlined our hardware processes and built the accountability we need to hit Mission 3 milestones.”

— Isaiah Janzen, Manufacturing Lead US, ispace-US

Overview

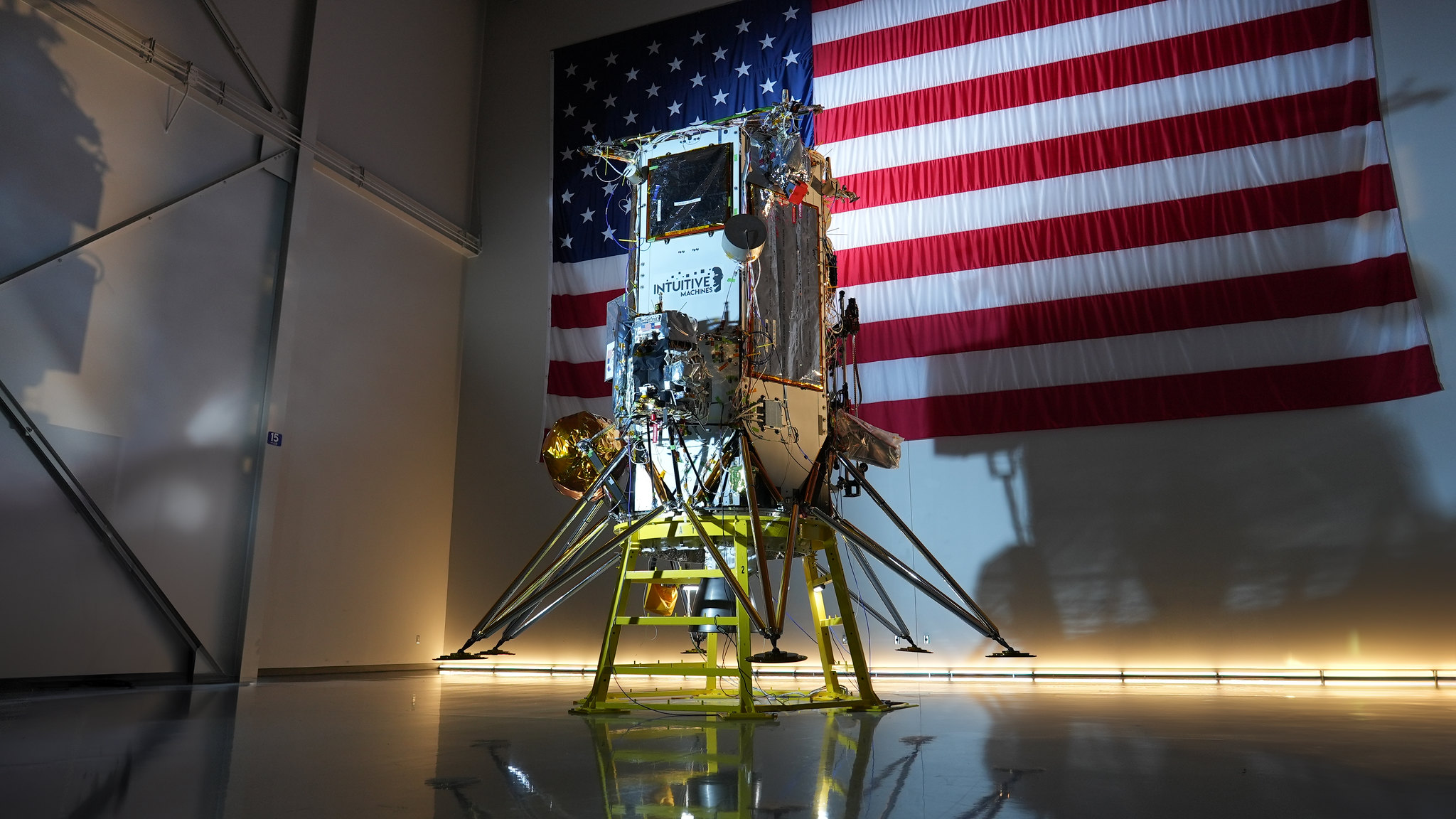

ispace, a global lunar exploration company, is scaling for its upcoming mission to the Moon’s far side (NET 2027). To meet high stakes demands, ispace adopted Boltline, the end-to-end platform built for complex aerospace hardware. It delivers seamless traceability, real-time global collaboration, and shop-floor workflows, accelerating precision and documentation across all sites.

Source: ispace Locations

Challenges

As ispace prepared for Mission 3 (Team Draper Commercial Mission 1), the team proactively identified challenges inherent to scaling high-precision lunar hardware, leading to traceability gaps, inventory inefficiencies, and risks of AI&T delays. With operations spanning multiple U.S. sites, Luxembourg, and Japan, multi-site coordination and cross-border compliance and collaboration were critical. Traditional software, designed for high-volume, low-mix production, lacked the flexibility needed for iterative, low-volume, high-mix development with evolving specifications.

Solution

ispace partnered with Boltline, an end-to-end engineering toolset, integrating it into their ecosystem with a unified platform tailored for complex hardware like lunar landers:

- End-to-End Traceability: Click-by-click tracking via Work Plan Runs logs every action, user, and timestamp, providing the excellent hardware traceability needed to know where parts came from, how they were handled, and who processed them when

- Mobile-First Workflow Integration: Tablets/iPads on the shop floor enable smooth work execution, including direct photo uploads into relevant steps, accelerating documentation without disrupting flow and supporting rapid iterations

- Real-Time Remote Monitoring: The web browser interface delivers live updates, allowing monitoring of ISO Class 7 clean room processes without entry and enabling real-time support from Englewood, Colorado, to multi-location and third-party sites

- Flexible Inventory and Process Management: Configurable modules, proven highly effective for inventory counts, adapt to diverse departmental needs beyond AIT, fostering efficiency across the organization

- Global Compliance Enablement: Boltline handles local standards, promoting secure collaboration, version control, and accountability that drives team buy-in, ensuring processes are done right the first time to avoid redoing complicated tasks on expensive hardware

Proven Results: Overcoming Challenges with Boltline

Boltline directly addressed ispace’s anticipated hurdles: traceability gaps, inventory inefficiencies, multi-site coordination, and compliance complexities, accelerating hardware processing at ispace-U.S. for Mission 3 while boosting efficiency, accountability, and global synergy. In the company’s first post-implementation inventory count of its multimillion-dollar flight hardware portfolio, Boltline achieved 99.9%+ accuracy, surpassing expectations and extending transformative benefits to additional departments like quality and logistics beyond initial AI&T focus.

About ispace, inc.

ispace, a global lunar resource development company with the vision, “Expand our planet. Expand our future.”, specializes in designing and building lunar landers and rovers. ispace aims to extend the sphere of human life into space and create a sustainable world by providing high-frequency, low-cost transportation services to the Moon. The company has business entities in Japan, Luxembourg, and the United States with more than 300 employees worldwide. For more information, visit: www.ispace-inc.com and follow us on X: @ispace_inc.